Journal

Sustainable Finnish craftsmanship

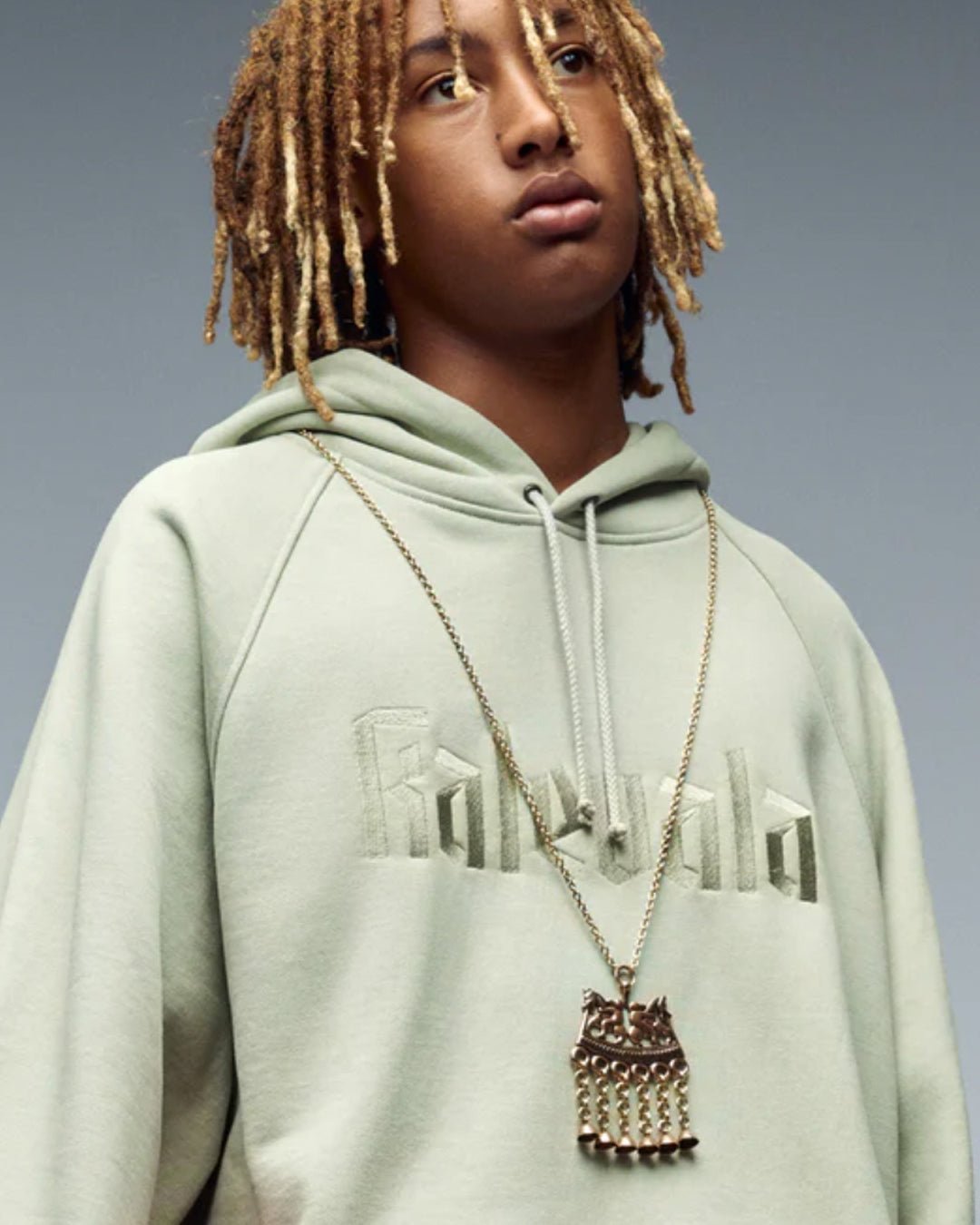

At Kalevala Jewelry's own factory in Helsinki, Finland, more than 70 jewelry professionals make each Kalevala jewelry by hand. Welcome to take a peek at Europe's most modern jewelry factory.

With Kalevala Jewelry, handmade really means handmade.

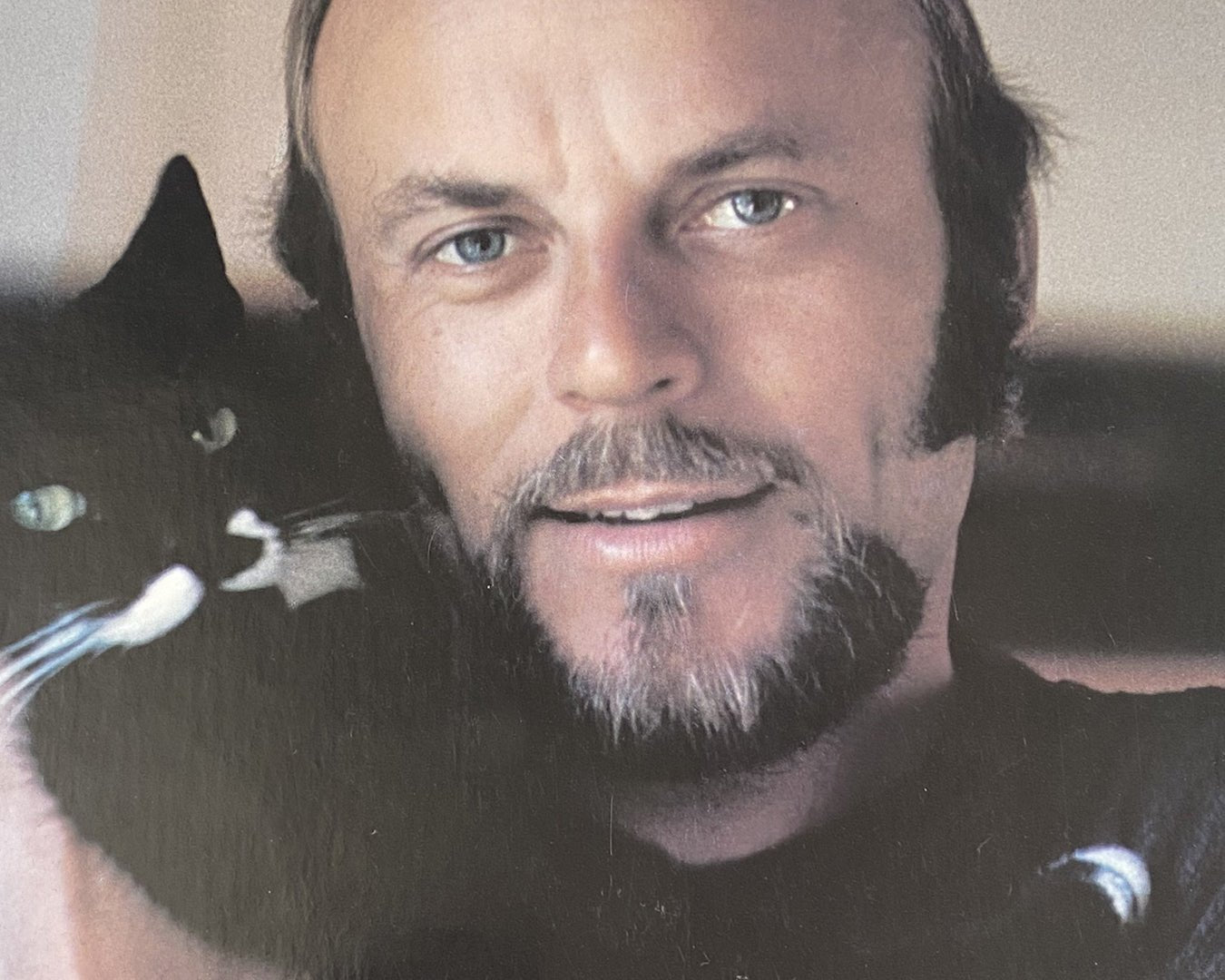

The nylon hammer hits the side of the metal tool, which rests against the solid birch plank. Goldsmith Petteri Karkkila leans closer to the plank, places a magnifying glass and hammers a thin gold plate.

We are in Goldsmiths' hall, in the heart of the Kalevala Jewelry factory. Around 200,000 handmade Kalevala jewelry are made every year at these wooden planks and work tables: earrings, bracelets, necklaces, pendants and rings, just like now.

With Kalevala Jewelry, handmade really means handmade. Ever since Elsa Heporauta founded Kalevala Jewelry in 1937, jewelry has always been made in Finland: for example, design, wax models, casting, pressing, hammering, drum polishing. All.

Goldsmith Karkkila examines a triangular ring blank around the metal surface. He grabs the gold in nylon pliers and twists the ends of the butt seam of the ring tightly together.

"If you rush here, you'll regret it later," says Karkkila.

The Goldsmiths' hall is only one part of the factory. Let's go further and see where goldsmiths get their blanks.

One piece of jewelry – ten pairs of hands

Each Kalevala piece of jewelry passes through ten pairs of hands before being completed. About half of the employees work in primary production.

The journey of cast jewelry begins in the wax department. First, a wax mold is made and a wax tree resembling a bonsai tree is built by hand, each leaf of which is a blank for one piece of jewelry. These trees are covered with a plaster mixture, and when the plaster has hardened, the wax is melted away. This way, only jewelry-shaped cavities remain inside the plaster, which are filled with molten metal.

"The casting technique is basically the same as the ancient Egyptians. They made molds out of beeswax, which were baked into a clay-sand mixture," says Kalevala Jewelry's Ville Jokela.

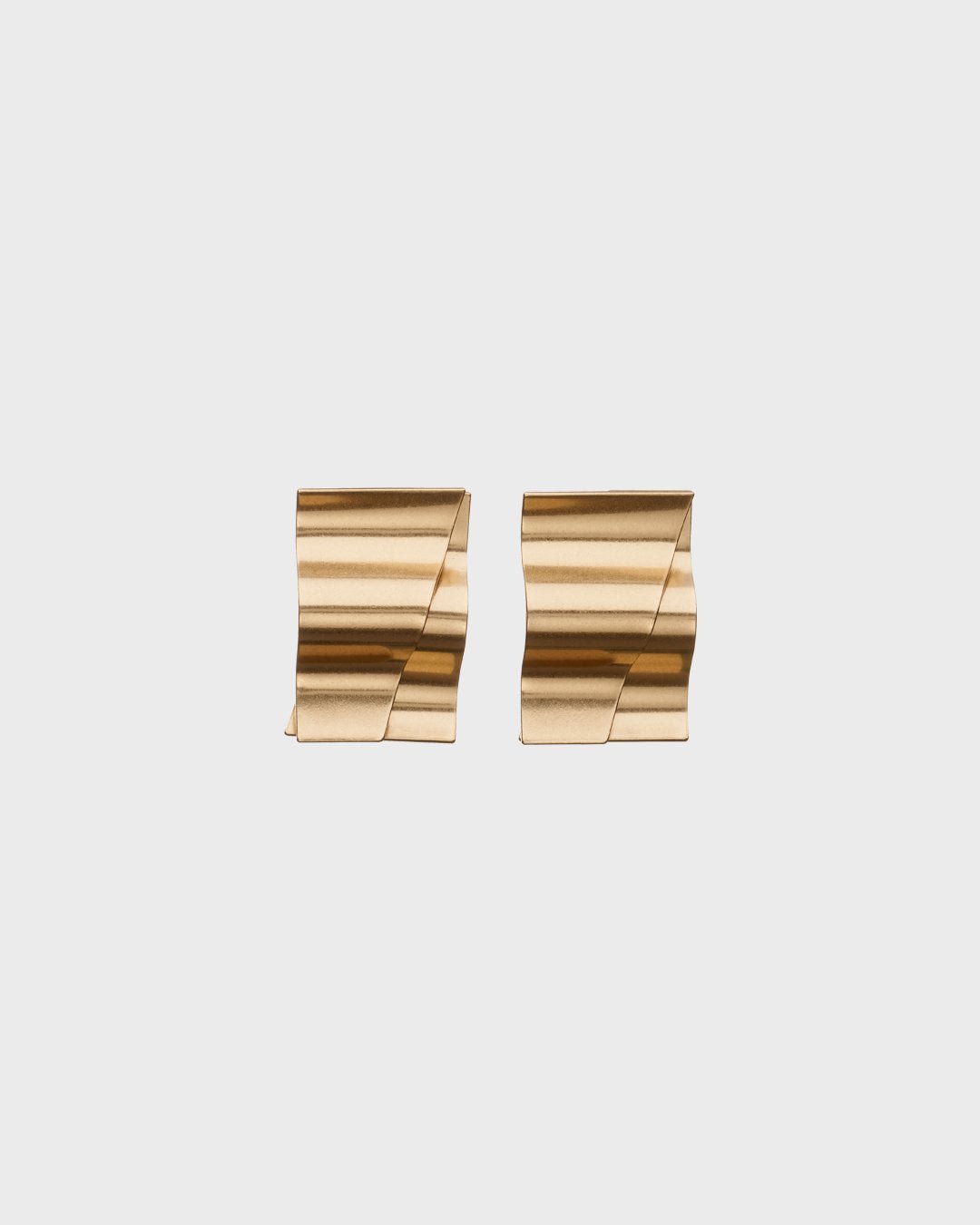

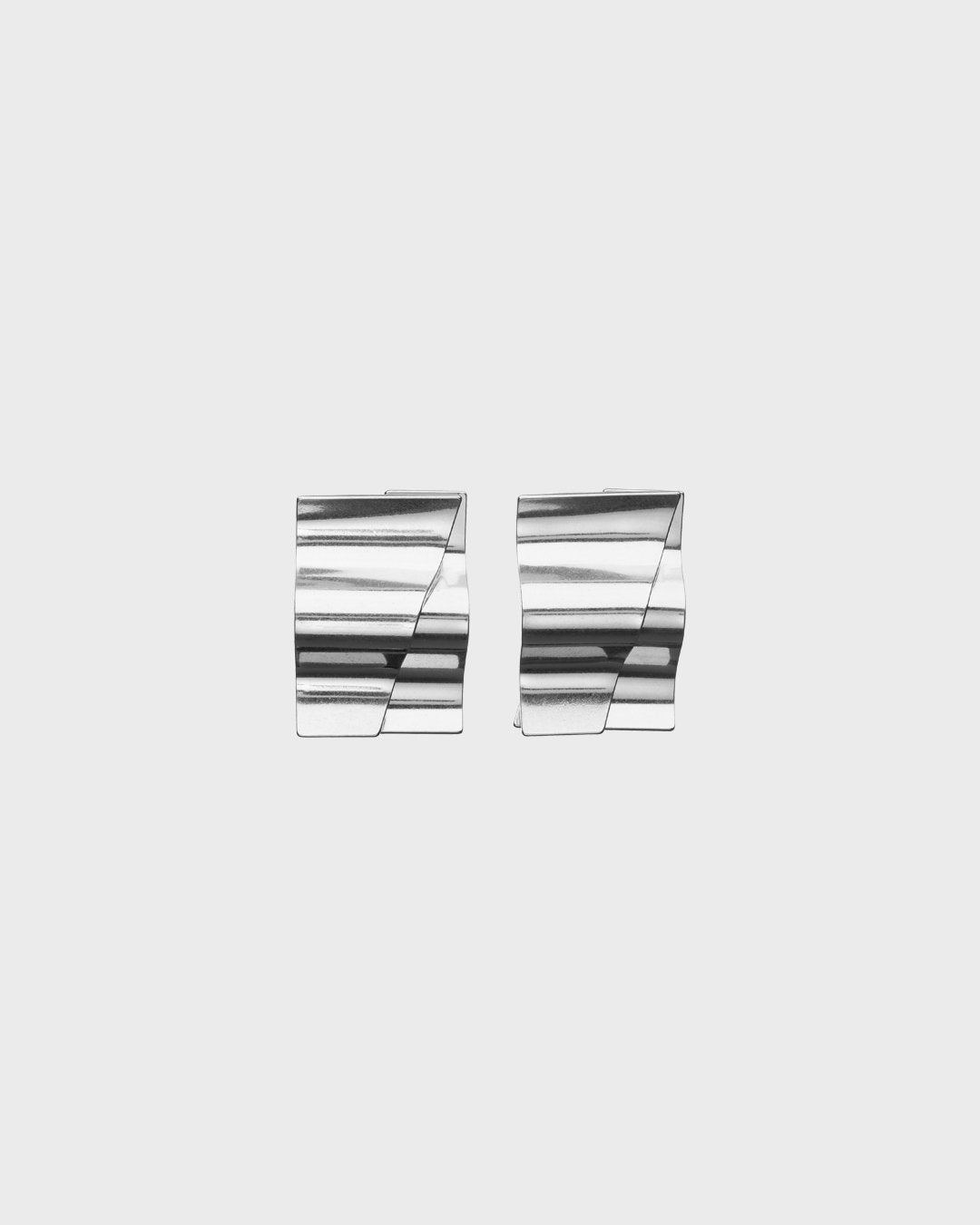

There is a muffled thump from behind the door next to the wax department. At pressing department, the blanks for all the Kalevala jewelry, which are made by pressing, i.e. by pressing a mold onto a metal sheet, are ready for the goldsmiths' hands.

Although the factory's oldest friction press, which hits with a force of thousands of kilograms, is from 1961, the wind-powered factory is also full of modern top technology, which enables the most responsible production possible. This technology can be found both under the floor and in large pipes through the ceiling.

Recycled precious metals also circulate in the factory

All of the gold in Kalevala jewelry is 100% recycled, over 99% of the silver and some of the bronze. This saves natural resources, as do the laboratory diamonds in the new Kalevala Love ring collection, which, as the name implies, are made in a laboratory and not mined from the ground.

Precious metal circulates in the factory as well - even the grinding dust is recovered using state-of-the-art technology and recycled for reuse.

The modern equipment located in the factory's drains separates the chemicals and metals from the water so precisely that the people of Kalevala Jewelry joke that they can almost drink it before it is discharged into the municipal sewer network.

On both sides of the factory's long corridors, there are spaces that you can peek into through large glass windows. Used Kalevala jewelry, future treasures of the Preloved secondhand service, have been collected in one of the premises. They are refurbished and, if necessary, surface treated here to make them like new before being put up for sale.

One of the crucifixes in the boxes is from the Continuation War period in 1941. It carries with it more than 80 years of memories.

The Love series ring is now taking shape in Karkkila's hands. One day, someone will give it to their loved one - and then you can be sure that it was also made with love.

A nurturer of old artisan skills

In the Goldsmiths' hall, goldsmith Petteri Karkkila bends over the ring again for the next work step, soldering the seam. He grabs the soldering gun and turns on the gas flame. Kalevala Jewelry is Finland's largest employer of goldsmiths and jewelry professionals and nurturer of artisan skills in Finland. Karkkila has worked at Kalevala Jewelry for over 20 years. Although the basics – fire, hammer, skillful hands – have remained the same in the goldsmith's profession for centuries, craftsmanship lives on and develops with the help of new innovations and challenges. An example of this is, for example, the rings of the Kalevala Love series, in which goldsmiths get to embed laboratory diamonds for the first time in their career. The Love series ring is now taking shape in Karkkila's hands as well. One day, someone will give it to their loved one - and then you can be sure that it was also made with love.

"This is a pretty cool job."

Vetovoima I Design Juslin Maunula

The Vetovoima bracelet is completed in the video

Blog author: Gut Studio