Finnish handicraft

Proudly made in Finland – and it shows. Every piece of Kalevala jewelry is handcrafted in Finland, combining timeless design with skilled local craftsmanship.

As a recognition of our commitment to Finnish work, Kalevala Jewelry has been awarded the Key Flag Symbol.The Key Flag is a trusted mark that stands for Finnish quality, sustainability, and responsibility. It tells you that when you choose Kalevala, you’re not just choosing beautiful jewelry – you’re supporting Finnish design, jobs, and values.

Each Kalevala piece of jewelry passes through an average of 10 pairs of hands before the piece is in the customer's possession

In our factory, the latest innovations of modern technology meet the centuries-old traditions of Finnish goldsmithing. Making jewelry is still very much a craft. Each Kalevala jewelry goes through an average of ten pairs of hands on the way from the blank to the finished piece.

Responsibly handmade in Finland: it is a value choice for us to make Kalevala jewelry in Finland, and to maintain Finnish goldsmithing skills and the tradition of jewelry making. This is how we have operated for nearly 90 years and we will continue to operate this way.

How is a piece of jewelry created?

Have you ever thought about how a piece of sheet metal or a handful of metal grains creates a piece of jewelry? What kind of methods and tools are needed for that, what kind of work steps and know-how? Below we will tell you about our two manufacturing methods, casting and pressing.

At Kalevala Jewelry, handmade really means made by hand.

Infusion

Most of our jewelry is made by casting. Our foundry has modern furnaces, casting machines, washers and flashing digital displays. Even though the technology has developed, the age-old basic principle has not changed – casting is pouring molten metal into a mold, where it solidifies into the shape of a piece of jewelry when it cools.

Metal casting has thousands of years of history behind it. Skillful jewelry was cast in Finland already in the Iron Age.

See in the video how the rubber mold, wax wood, metal cylinder and plaster are connected to the production of the Diamond Branch gold ring and how the designer's sketch creates a piece of jewelry skillfully made by Finnish handcraft.

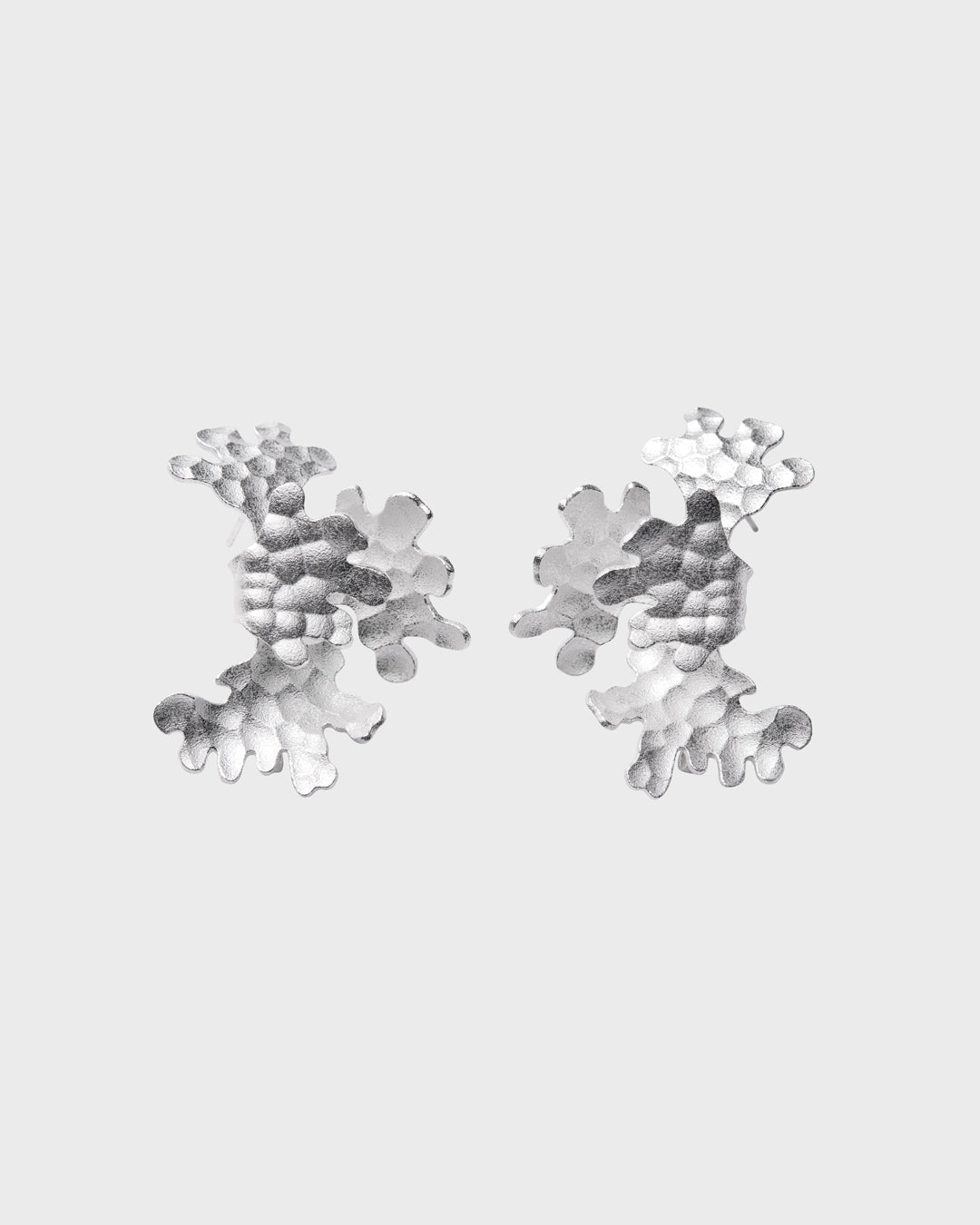

Nämä korut on valmistettu valamalla

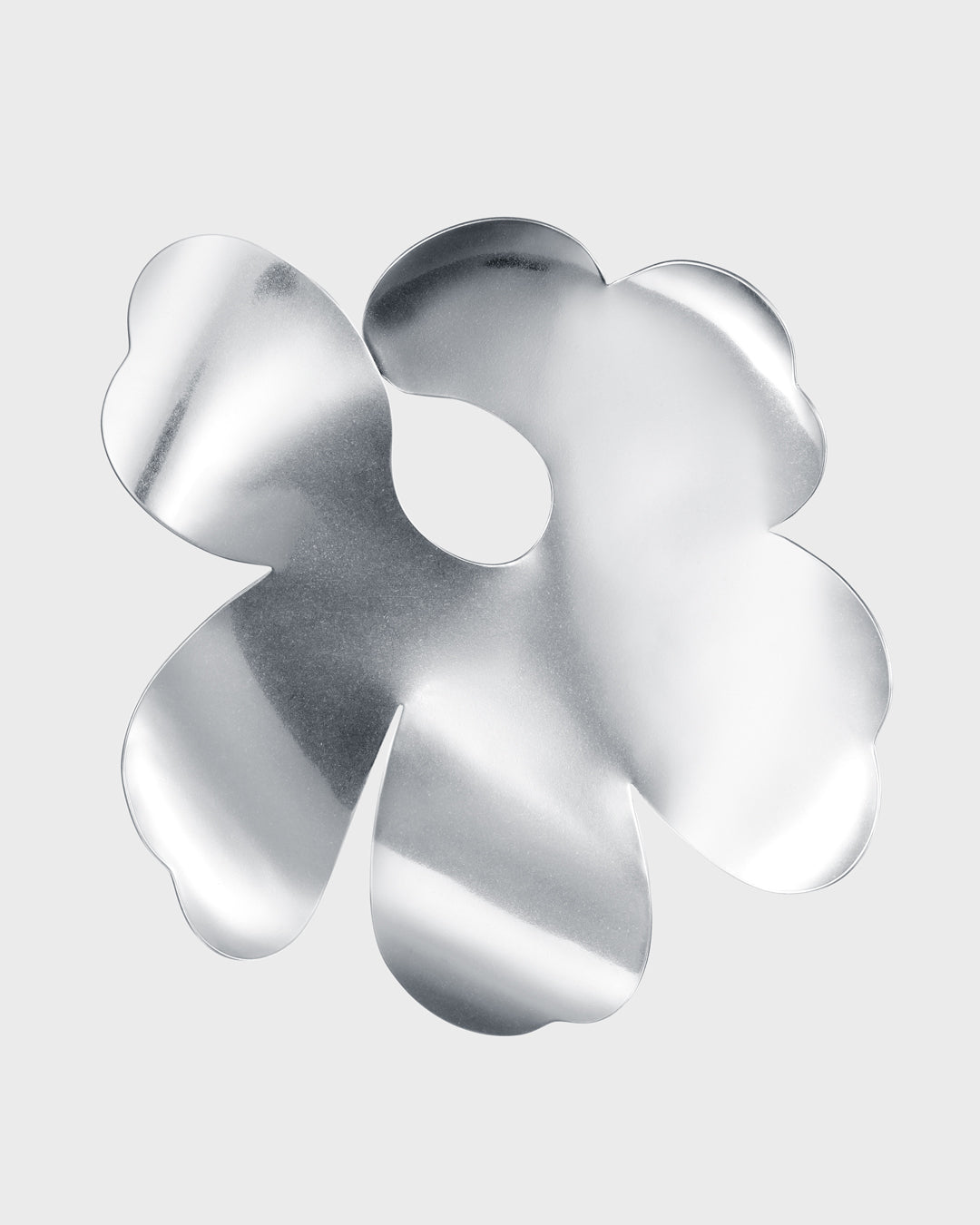

Pressing

In pressing, the shape and decorative pattern of the jewelry is punched into a metal sheet using steel molds. The press room of our factory has a genuine old-time machine shop atmosphere: the smell of lubricating oil, sturdy machines, the oldest of which have served for more than half a century, and often quite a bang. The metal pieces slam against each other with the compressive force of thousands of kilograms. Even the smallest and most delicate jewelry can require raw strength to be born.

For example, the multi-stage journey of the beloved Heart Ring starts from the blanks struck in the press room and finally ends through ten pairs of hands as a finished piece of jewelry.

Nämä korut on valmistettu prässäämällä

"If you rush here, you'll regret it later"

Take a look at Europe's most modern jewelry factory in the Kalevala Journal article and you'll find out where to slow down.