Responsibility

Responsibility is strongly at the core of our strategy and our company's business is developed sustainably.

Kalevala Preloved has claimed its place on the secondhand market

In January 2022, we piloted the Kalevala Preloved service at the Kalevala Outlet operating in connection with our factory. The popularity of used and refurbished Kalevala jewelry surprised us, and in November we also opened the Preloved service in our Kalevala.fi online store. In May 2023, we expanded Preloved to include also designer jewelry from Lapponia.

Preloved has quickly become a favorite of our customers and also of our staff. We have sold over 15,000 Kalevala Preloved jewelry that we refurbished to their original glory. The story of our jewelry continues.

We want to make less completely new jewelry, and invest in extending the life cycle of existing jewelry

Kalevala maintenance service

Kalevala Preloved is part of Kalevala Jewelry's responsibility and transition towards a circular economy. We envision that in 2030 used Kalevala Preloved jewelry already covers 20% of the volume of our own Kalevala stores and online store.

The purchase and maintenance of used Kalevala jewelry also changes the focus of our own factory's operations: We want to make less completely new jewelry, and invest in extending the life cycle of existing jewelry.

This is possible because we manufacture and maintain all Kalevala jewelry at our own factory in Helsinki, Finland. Our maintenance service is also known for its high quality.

Get to know the Kalevala maintenance service.

Renewable, innovative biomaterials

We do continuous product development and look for new, sustainable solutions, materials and methods. We are currently testing the potential of bio-based materials.

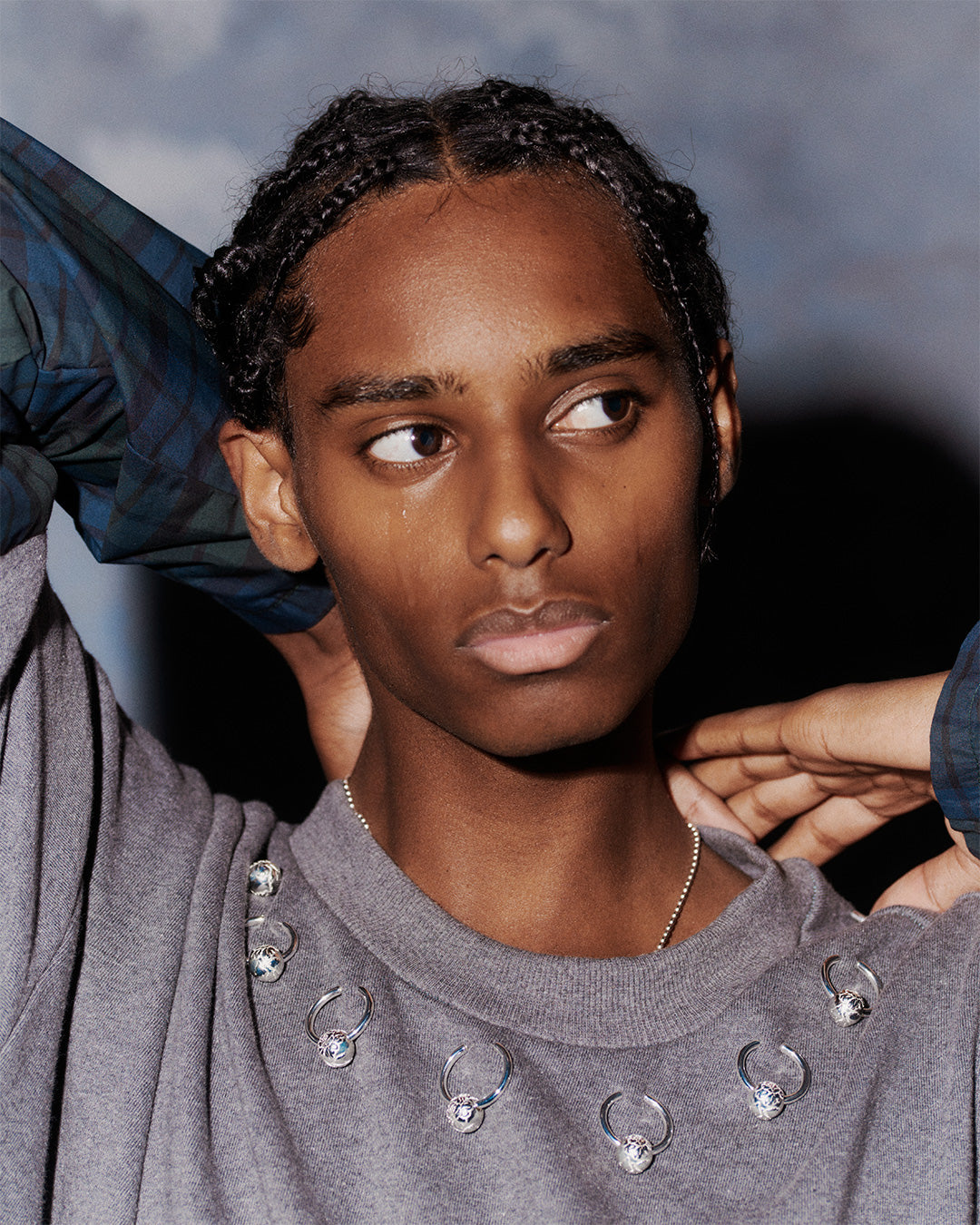

The Nolla jewelry series brings the renewable, innovative biomaterials of the Finnish company Brightplus to Kalevala jewelry. The inspiration, colors and manufacturing materials of the Nolla jewelry series come directly from nature.

Biomaterial is made from plant-based sources, such as hemp, sugar cane and legumes. The new biomaterial used in the jewelry is a plastic-like, renewable raw material developed in Finland that does not leave long-lasting microplastics that are harmful to the environment at the end of its life cycle.

The colors also come from nature: black color from soot, blue from woad and green from metal oxide. The silver parts of the jewelry are 100% recycled.

Read more about Nolla and renewable biomaterial in the Kalevala Journal article.

The recycling rate of metals is very high

Kalevala jewelry uses three main materials: gold, silver and bronze. We have a high recycling rate for these metals; in gold a full 100% and in silver more than 99%. A few individual pieces of silver jewelry have a recycling rate of less than 100%, and our goal is a 100% recycling rate for them in the next few years as well.

Bronze is more challenging for us in terms of transparency, because it is a metal alloy and is produced with different degrees of mixing, e.g. of copper, zinc and tin. The material flows of these substances are huge in the world and it is challenging to define the recycling rate for them. The work continues and our goal is to increase the recycling rate of bronze as well.

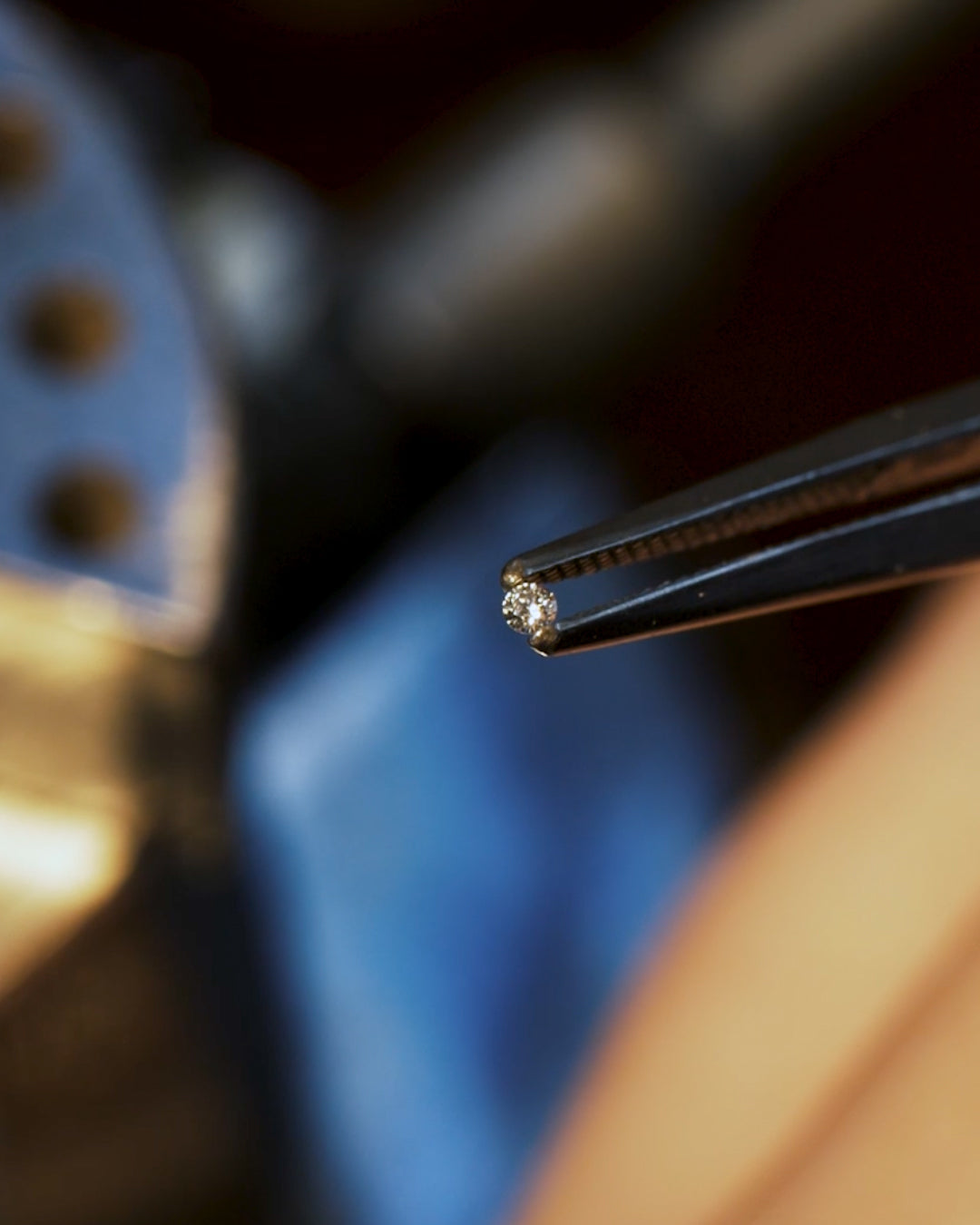

In addition to using recycled precious metals in the manufacture of jewelry, we accurately collect the precious metal waste generated during the manufacture. All precious metal waste is recycled and cleaned for reuse – even the metal dust generated during the grinding process.

For us, handmade really means handmade. All Kalevala jewelry is made domestically in our own factory in Helsinki, Finland.

A modern and responsible jewelry factory

The Kalevala Jewelry factory in Helsinki is one of the most modern in Europe. We use energy-saving LED lights and the electricity we use is produced by wind power and solar panels located on the roof of our factory.

We have renewed the technology of the process water treatment system and switched to modern vacuum distillation. Our factory has state-of-the-art equipment that very precisely and energy-efficiently separates chemicals and metals from the process water generated in the various stages of jewelry manufacturing. We discharge part of the purified water into the sewer network and recycle part back into the production processes. We keep the sewage network clean and reduce our factory's water consumption.

Read more about our responsible manufacturing.

Responsibly handmade in Finland: it is a value choice for us to make Kalevala jewelry in Finland, and to maintain Finnish goldsmithing skills and the tradition of jewelry making. This is how we have operated for 87 years and we will continue to operate this way.

Responsibility for Finnish jewelry manufacturing

As Finland's largest company in the jewelry industry and as an employer of goldsmiths, we have a key role and responsibility as a nurturer and developer of the traditions of the Finnish goldsmith industry. By keeping the production of Kalevala jewelry in Finland, we ensure that jobs and know-how in the field will continue to be preserved in Finland.

Each Kalevala piece of jewelry passes through an average of 10 pairs of hands before it is in your hands as a customer. If you are interested in jewelry making, read about how jewelry is created as a Finnish handcraft in Helsinki

Together for cancer research

Cancer Foundation Finland is the country’s leading private funder of cancer research, and the Pink Ribbon is its most recognized campaign. Kalevala Jewelry has supported the campaign since 2015 with a dedicated Pink Ribbon jewelry piece. Together with our customers, we have donated 357,000 euros to cancer research.

The Pink Ribbon 2025 piece, Circe of Light, symbolizes friendship and hope. For every Pink Ribbon 2025 piece sold, Kalevala Jewelry will donate 10 euros to Cancer Foundation Finland. Read more

One-third of Kalevala Jewelry’s profit is annually donated to charity projects and the well-being of the employees

More than 600 young women have graduated from the Kalevala Training Center

For the past five years, we have been cooperating with Home Street Home, the association responsible for the Kalevala Training Center in Makongen, Kenya. The training center is fully financed by Kalevala Jewelry.

More than 600 young women have graduated from the Kalevala Training Center. 78% of graduates have found a job, started a company or are continuing their studies.

Get to know the Kalevala Training Center

In the spring of 2022, we started cooperation with the national association of disabled women, Rusetti ry, and with our support, Finland's first vammaisettytöt.fi media was founded by disabled girls for disabled girls.

Read more about the Kalevala x Vammaisettytöt.fi collaboration

The climate crisis and loss of nature will put pressure on companies and society to change in the coming years. Business and product consumption must be developed in a more sustainable direction, enabling the well-being of the environment alongside people and economic well-being.

Towards a carbon-neutral circular economy. Our goals and measures we focus on.

- We are further developing the Kalevala Preloved service so that it covers 20% of the volume of Kalevala's own channels in 2030.

- In 2025, we will calculate our full value chain (scope 3) emissions and prepare an emission reduction plan towards carbon neutrality by 2035.

- We are improving the transparency of the bronze recycling rate.

- We are investigating the possibility of replacing the oil-based plastic used in the storage of Kalevala jewelry with a fossil-free material.

- We will continue to finance the operational activities of the Kalevala Training Center and other possible charity projects. Our goal is that the projects we support achieve self-sufficiency in the longer term.